Measuring the temperature of your fridge and freezer and setting up alerts for temperature breaches is crucial to ensure goods are stored correctly. This is especially important for perishable items like food and medicine, as they stay fresher for longer when stored at the right temperatures.

Companies in various industries must adhere to regulatory standards to prevent any potential harm from incorrect storage conditions. According to the Food Standards Agency it is a legal requirement that chilled food is stored below 8°C, with fridges ideally set at 5°C and below. Regular temperature checks and record-keeping are essential for due diligence and to comply with safety standards.

In the life science industry, refrigeration is also vital for storing samples at the correct temperatures to ensure accurate research results.

By utilising various methods to measure temperature and set alarms, you can proactively address any issues before goods are compromised.

Methods for Measuring Temperature and Setting Fridge Alarms

Receiving an early warning about a temperature anomaly within your appliance is crucial, providing you with valuable time to assess and address the issue before goods are spoilt and losses incurred.

One way to achieve this is by using a basic alarm system like thermometers that not only display the temperature on a screen but also emit an audible alarm when fridge/freezers temperatures surpass a specific threshold. For compliance purposes, however, recording temperature readings must be done manually.

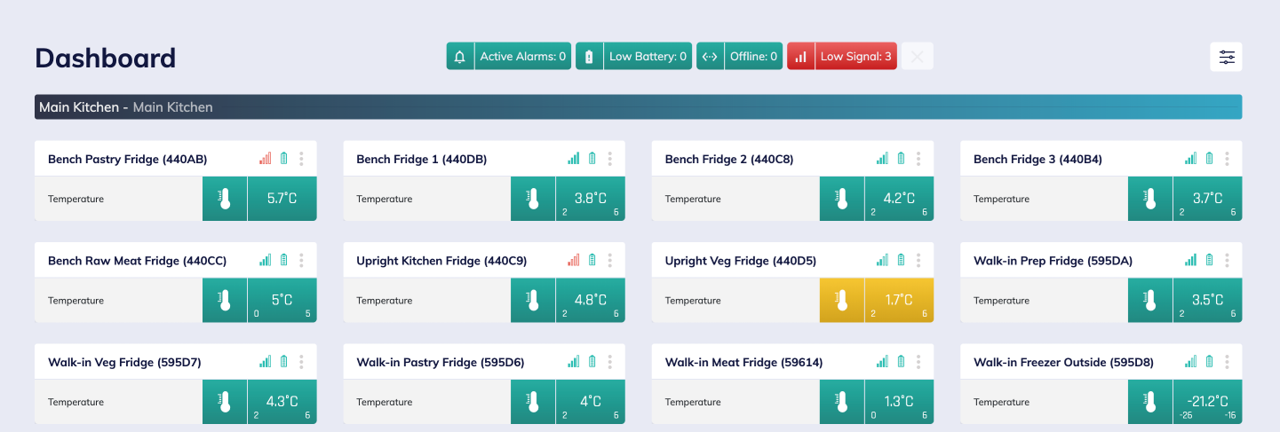

Alternatively, there are more advanced solutions that alert staff on their PC, Laptops and Smartphones by initiating a telephone call, sending a text message or email. These automated solutions often use wireless IoT sensors and help to fulfil compliance obligations by automatically recording the temperature of your appliances 24/7 on an online platform.

Alternatively, there are more advanced solutions that alert staff on their PC, Laptops and Smartphones by initiating a telephone call, sending a text message or email. These automated solutions often use wireless IoT sensors and help to fulfil compliance obligations by automatically recording the temperature of your appliances 24/7 on an online platform.

Key Considerations for Evaluating Temperature Monitoring Methods

While thermometers are appealing due to their low cost, they may not address all the challenges encountered when adopting them. So, what other factors should you consider?

Compliance: If your business is operating in the food sector, you’ll likely require temperature readings to comply with safety standards. Automated systems offer easier compliance management with real-time monitoring and digital record-keeping.

Resource Allocation: How much time and labour can you dedicate to monitoring? Manual systems may be resource-intensive, whereas automated systems free up staff to focus on more skill-based tasks.

Cost of Goods Stored: What is the cost of replacing spoiled goods? Automated systems can prevent spoilage by sending real-time alerts, protecting valuable stock.

Night-Time Faults and Power Cuts: Can a basic fridge alarm alert you out-of-hours when an appliance fails or there is a power cut? Advanced systems can send alerts even at night, ensuring you’re notified of potential risks.

Reputation and Customer Impact: How would spoilage or compromised quality affect your reputation? Continuous monitoring ensures goods are stored properly, protecting your brand image.

Alarm Fatigue: Does your basic alarm (thermometer) system trigger unnecessary alarms? Customisable settings can reduce false alarms, preventing staff from ignoring critical alerts.

Technological Advancements in Fridge Alarm Systems

Fridge alarm systems have evolved significantly, incorporating modern technology to deliver more precise and real-time monitoring. These advancements provide businesses with better control and insight into their refrigeration systems. Below are some of the latest features in advanced fridge alarm systems:

Wireless IoT Sensors: Modern systems use wireless sensors to constantly monitor temperature. These sensors eliminate the need for manual checks and are easy to install.

Cloud-Based Monitoring: With cloud-based data storage, users can access temperature records from anywhere, making monitoring across multiple locations seamless.

Energy Efficiency Insights: Advanced systems provide data on energy consumption, helping businesses optimise energy use and reduce costs.

Remote Diagnostics and Troubleshooting: Some systems offer remote diagnostics, allowing technicians to resolve issues without needing to visit the site.

Multi-Device Compatibility: Real-time alerts such as SMS, phone calls, emails can be sent to multiple devices PC, laptops and smartphones, ensuring that the appropriate team members are always informed.

AI-Powered Predictive Alerts: With the use of AI historical data can be analysed to detect unusual temperature patterns and send predictive alerts, enabling businesses to take action before issues arise.

How to Choose the Right Fridge Alarm System

Selecting the right fridge alarm system depends on various factors that align with your business’s unique requirements:

Compliance Requirements: For industries with strict temperature regulations, an automated system that logs temperature data and generates compliance reports is essential.

Alarm Customisation: Look for a system that offers advanced alarm customisation to prevent unnecessary alerts and ensure you’re notified only when necessary.

Ease of Use: Opt for systems with intuitive dashboards and simple installation to reduce the learning curve for your team.

Scalability: If you have multiple locations or plan to expand, choose a system that can monitor several units and locations from a centralised platform.

Data Access and Storage: Cloud-based systems provide instant access to historical temperature data, which is crucial for audits, compliance, and optimising performance.

Cost: While basic systems are cheaper, investing in an automated system can offer better long-term savings through improved efficiency and reduced risk of spoilage.

Future Proof: Choose a system that can monitor other conditions as and when required and therefore address future requirements as your business evolves.

Benefits of Automated Fridge Alarm Systems

Automated fridge alarm systems offer numerous benefits compared to traditional thermometers:

Continuous Monitoring

Traditional thermometers require manual checks to monitor temperature, whereas automated systems provide continuous, real-time monitoring. This ensures that any temperature fluctuations are detected immediately, even between manual check intervals.

Better Compliance Management

Automated systems simplify compliance by automatically storing data, generating reports, and offering easy access during audits or inspections. This is far more efficient than manually maintaining temperature logs, which are required when using traditional thermometers.

Historical Data and Trend Analysis

Automated systems store historical temperature data, allowing users to analyse trends over time. This is useful for identifying recurring issues, optimising temperature settings, and ensuring that appliances maintain the desired conditions consistently. Traditional thermometers offer no such capability.

Proactive Maintenance

With predictive analytics and alerts, automated systems can detect patterns that indicate potential equipment failure, such as irregular temperature fluctuations. This allows for proactive maintenance and reduces the risk of unexpected breakdowns, which traditional thermometers cannot predict.

Remote Monitoring

Automated systems allow users to monitor their fridges remotely via mobile devices, computers, or tablets. This feature is particularly useful for multi-location businesses, enabling central monitoring without being physically present. Traditional thermometers require someone on-site to check temperatures, making them less practical for remote management.

Faster Response to Issues

Automated systems send real-time alerts via SMS, email or via phone calls, enabling staff to respond faster to temperature breaches. In contrast, traditional thermometers require someone to physically notice the issue, which can delay corrective action and increase the likelihood of spoilage.

Error Reduction

Since automated systems log data electronically, there’s less risk of human error. Manual recording, which is required for traditional thermometers, can be prone to mistakes, missed checks, or inaccurate entries. Automated systems eliminate these risks by ensuring all data is captured accurately.

Customisable Alarms and Notifications

Automated systems allow you to set highly customisable alarm thresholds based on your specific needs. For example, different alerts can be set for day versus night, or different appliances. Traditional thermometers generally have basic audible alarms with limited customisation options.

Reduced Labour Costs

By eliminating the need for manual checks, automated systems save significant time and labour costs. This allows staff to focus on higher-value tasks, unlike traditional thermometers that require consistent monitoring and manual recording.

Increased Accountability

With automated monitoring, there’s a digital audit trail of who received alerts and what actions were taken in response. This increased accountability ensures that corrective measures are always tracked, whereas traditional systems rely on manual documentation, which can be easily overlooked or forgotten.

Conclusion

While fridge thermometers can assist in measuring fridge temperature, utilising them to meet regulatory standards requires the traditional method of pen and paper. On the other hand, system-based solutions offer automated, accurate, reliable, efficient, and cost-effective temperature monitoring. If you find yourself in a bustling environment with limited time to spare, isn't it time to transition to a more advanced, automated solution?

If you would like a demonstration, pricing or more information about our temperature monitoring solution, please get in touch with us. You can find all our contact details by clicking on the contact us tab at the top right of this page.