Introduction to Fridge Temperature Monitoring

It is a common practice to store items at colder temperatures to help prolong their shelf life and preserve their quality over time. However, if the optimal temperatures are not maintained, it can have adverse effects on the goods.

The consequences of improper storage can vary depending on the type of goods. For example, storing chemical-based products incorrectly could lead to selling subpar items, impacting customer satisfaction and loyalty. On the other hand, consuming improperly stored foods and medications could have serious life-threatening repercussions, such as food poisoning or reduced effectiveness of medication.

To prevent such incidents, regularly monitoring appliances and checking temperature readings is crucial to ensure they are functioning correctly and maintaining the desired storage conditions. This is either done manually or by using automated monitoring technology.

Risks and disadvantages of manual systems

A manual process involves checking each unit 2-3 times daily and recording its temperature on paper. This helps to prevent goods subjected to higher temperatures (due to faulty equipment) being sold or consumed by an unsuspecting customer. Recording and documenting these checks is necessary to show a robust, reliable process that complies with UK standards.

However, this process is far from perfect. It takes time and is repetitive, menial work and though crucial given the consequences, it’s dull work that no one wants to do. In busy environments such tasks are often rushed causing inaccurate information being recorded. Without a reliable and dependable process in place, increases the chances of substandard products being sold putting both consumers and your business at greater risk.

Furthermore, manual checks aren’t done frequent enough to prevent waste. For instance, if an issue with an appliance occurs soon after a check is complete or during the night, products may be exposed to unsafe temperatures, resulting in potential loses. If there’s ever any doubt, goods are often discarded.

Overview of automated fridge temperature monitoring systems

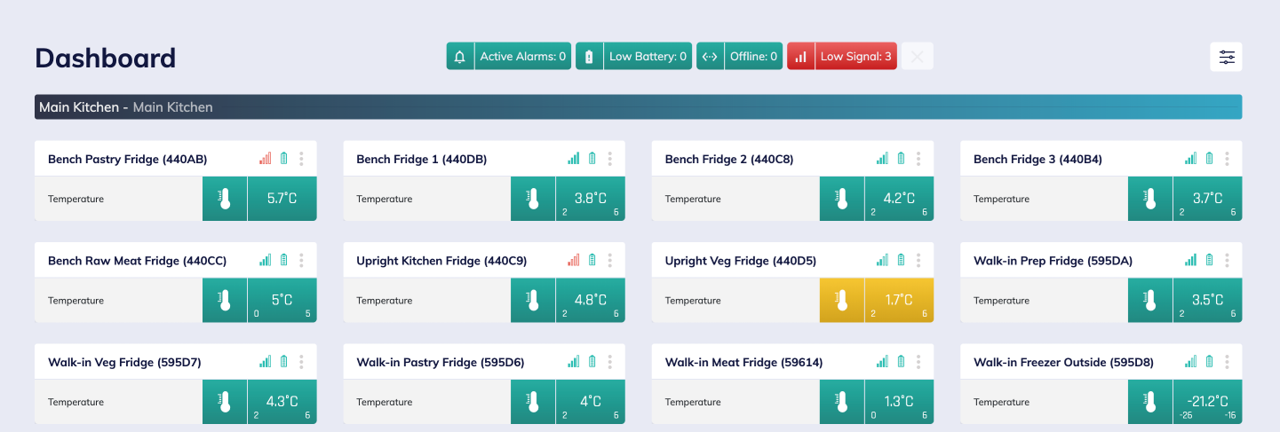

Automated monitoring systems on the other hand can collect the data automatically in regular 10-15 mins intervals throughout the day and night. The data is reliable and can be viewed in real-time on dashboards, with historical information available in charts. This approach makes compliance with regulatory standards far easier, as temperature records are accurate and detailed.

Automated systems also trigger alarms when fridge temperatures rise unexpectedly, giving staff ample time to address the issue or transfer goods to another unit. By reviewing historical temperature data, users can assess whether goods have been exposed to unsafe conditions and decide whether they should be discarded or salvaged.

Additionally, historical data simplifies the process of setting appliances to their optimal temperature, leading to energy savings and cost reductions.

How Fridge Temperature Monitors Operate

Temperature sensors are either installed inside appliances or mounted externally with a wire probe fed through the door seal. The sensor measures the temperature and transmits the data to a system application, where it can be viewed in useful dashboards and charts. Systems can either reside locally on the network or in the cloud.

Solutions and components do vary. Modern systems use wireless sensors as they're easier, faster and cheaper to install without having to run extensive cabling. Wireless sensors vary in terms of (connectivity) how they connect and transmit data. Some rely on mobile networks or WiFi, others transmit to beacons or gateways connected either to the corporate or mobile network or a combination of both.

Advantages of Remote Fridge Monitoring Systems

Cost Savings and ROI

Automated systems not only enhance accuracy but also generate significant cost savings. By preventing product losses due to improper storage and minimising manual labour, businesses can reduce waste and optimize energy consumption, leading to a quick return on investment (ROI). Fewer product spoilages and less human intervention mean long-term savings.

Environmental Impact

Another critical benefit of automated temperature monitoring is its contribution to sustainability efforts. By reducing waste and improving energy efficiency, businesses can lower their carbon footprint, aligning with environmental goals and corporate social responsibility initiatives.

Benefits of remote access and control

Having access to the system remotely is beneficial if you manage one site or multi-sites. Everyone can see the data in one secure place. This saves time as information is readily available and easily accessible from any PC, laptop and smartphone. Users don't need to waste time requesting reports from colleagues or searching for them in offices or by accessing a specific PC where the information resides.

Furthermore, users can be given rights to access the data relevant to them. For example, chefs may have rights to see their restaurant data only, whereas others like Health & Safety may have access to see all sites.

Real-time data logging and alerts

Current information and alerts help prevent unnecessary waste and upset customers due to supply issues. Fridge malfunctions, power outages, or doors left open can expose goods to unsafe temperatures, leading to their disposal. Alerts notify staff when temperatures reach a certain threshold, providing ample time to address the issue. This not only helps save stock and reduce costs but also alleviates the burden and stress of quickly replenishing goods to fulfil customer orders.

Choosing the Right Fridge Temperature Monitoring System

When choosing a monitoring solution there are many things to consider. Price is no doubt one, but it must work too and be easy to adopt, otherwise staff won’t use it. Ease of deployment is crucial to ensure operations isn’t disrupted, as is ease of maintenance – as no one will appreciate a constant “task list” to keep the solution running. Security, scalability and future proofness are also normally high on the list too when choosing the right monitoring solution.

So based on the above criteria, the key functions and features to look for in a temperature monitoring system are as follows:

Long Range Wireless Sensors

It is important to bear in mind that appliances are like big metal boxes often situated in different rooms, floors, basements and outdoor areas. If you want something that is easy to deploy and won't disrupt normal business operations, wireless sensors are best as these can be installed quickly within the fridge itself.

There are all sorts of different wireless sensors available on the market. The best ones for fridge monitoring are LoRaWAN sensors as these have the longest range. Bluetooth and WiFi sensors have a range of approximately 50 and 100 metres respectively. This may sound long, however, this distance is reduced significantly by interior walls and even more so by the walls of the fridge. This usually results in a high number of Bluetooth beacons or additional access points being deployed to cover all areas where appliances reside. This not only increases the overall cost but impacts the speed and ease of deployment, and ongoing internal maintenance due to the amount of hardware and points of failure of the solution.

LoRaWan sensors, on the other hand, are ideal for monitoring fridge temperature due to their long range, wide area capabilities. They have a range of approx. 12KM direct line of sight. The signal does get decimated also by fridge and interior walls but still leaves plenty to play with.

This makes the solution easy to set up and install, with sensors placed in the appliance itself rather than mounted on the outside. It also means fewer gateways are required to cover the site making cost effective too.

The low powered nature of LoRaWAN means they can operate for approx. 3-5 years before batteries need replacing making them easy to maintain too.

Connectivity – Gateways

LoRaWAN long range capabilities also means that fewer gateways are necessary, which not only reduces the overall cost but makes the solution easy to deploy and maintain as there are fewer points of failure. 4G / LAN gateways can come with multi-net roaming SIMs that automatically roam onto an alternative 3G, 4G network should one fail. The solution can fall back onto the corporate network (if connected) in the unlikely event there is an issue with all mobile networks. Furthermore, gateways can be duplicated to provide further resiliency and redundancy.

By adopting 4G gateways the solution can be deployed independently from the company network. This is a great benefit as it means there is no added risk from a network security perspective, making it easier for IT Teams to approve and to deploy. The solution is also far easier to manage from a fault and maintenance perspective too. Any issues can’t be down to the network, which means the supplier of the solution has total ownership and accountability.

SaaS Monitoring Solution

As the system resides in the cloud, solutions are quick to deploy. IT teams don’t have the same security concerns with installing hardware or approving software on their network. Nor are they burdened by resolving issues should faults arise from time to time, or having to budget for system and software upgrades and maintenance costs.

With SaaS, you also don’t have to pay for spare capacity in case you scale, you pay for what you use. This provides the flexibility to start small and scale as the business requires it.

Some SaaS monitoring solutions, but not all, can monitor many other conditions such as energy consumption, ambient temperature, oven temperature, humidity, noise and air quality. By providing the option to add a variety of different sensors to the platform when required means the solution can address future requirements as the business needs evolve.

The application must be intuitive and user friendly to ensure successful adoption. Intuitive navigation should help guide users to find current and historic temperature information with minimal training. Scheduled reports should be configurable and emailed to users automatically to save time.

As well as temperature information, a dashboard that shows the status and performance of all components makes the general upkeep and ongoing maintenance far easier. For example, displays that show sensor battery life and online/offline status of gateways provides a snapshot of overall system performance. Technical alerts should be configurable to alert stakeholders when a fault has occurred, and when remedial action is necessary.

Compliance and Standards

Automated fridge temperature monitoring systems ensure adherence to UK regulations by continuously tracking and recording temperature data at regular intervals throughout the day and night. Unlike manual checks, which are typically conducted only a few times a day and are susceptible to human error, automated systems provide a more reliable and consistent record.

Digital sensors used in these systems maintain high accuracy, deviating by only a small margin annually (approximately 0.03°C). This ensures that even after years of use, the data remains precise. Additionally, these sensors can be calibrated by certified professionals, providing the necessary documentation to verify the accuracy of the readings. This robust process not only supports regulatory compliance but also enhances overall quality control.

Conclusion

Optimising fridge temperature monitoring is crucial for preserving the quality and safety of stored goods, whether they be food, medication, or chemical-based products. While manual monitoring can help maintain compliance, it’s time-consuming, prone to human error, and often insufficient for preventing waste or ensuring quality. Automated systems, on the other hand, provide real-time monitoring, remote access, and timely alerts, reducing labour while enhancing accuracy and reliability. By choosing the right technology—such as LoRaWAN sensors, cloud-based SaaS systems, and secure gateways—businesses can streamline operations, protect product integrity, and ensure regulatory compliance with minimal maintenance effort.