Statistics from the Health and Safety Executive (HSE) shed a sobering light on the issue of health and safety in the manufacturing industry. These statistics indicate that around 10% of the workplace fatalities that occur each year in Britain's workforce happen to employees in the manufacturing industry. Out of every 5 manufacturing industry employees, 1 of them (20%) has sustained a non-fatal injury at some point in their career. Put another way, the HSE reports that 330, 000 manufacturing industry workers annually (out of a total of 3.2 million in the sector) suffer sickness or injury in the workplace that is directly related to their job. Lone workers make up a larger proportion of these statistics due to the unique and heightened risks to which they are exposed in the workplace. It is clear that more needs to be done by managers to prevent death and injury in the manufacturing industry. This can be done by paying particular attention to the safety of lone workers.

Hazards associated with the manufacturing industry

Each manufacturing business is unique, and will present its own individual challenges to cope with. Nevertheless, here are some of the most common hazards that occur in the manufacturing industry (sources: OHS Union and HSE details on the manufacturing industry):

- Slips, trips and falls - this can happen in any part of the manufacturing industry

- Burns - this can happen in (for instance) the metalworking sector of the manufacturing industry where molten metals are being dealt with, or in chemical-based manufacturing processes which can result in chemical burns

- Cuts or broken bones due to working dangerous machinery: many sectors of the manufacturing industry harbour this risk, including the woodworking and shipbuilding industries

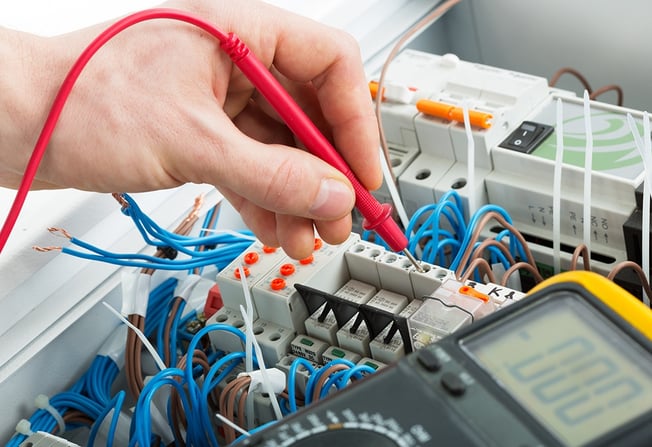

- Electric shocks - a potential danger when any type of electricity is being used

- Succumbing to dust or fumes - workers dealing with everything from concrete to plastic and glass manufacture can be exposed to this risk

- Falls from a height - the food manufacture industry is just one example where workers may be working at a height

The HSE gives a more comprehensive list of workplace hazards, specific to each sector of the manufacturing industry.

Why lone worker safety should be of paramount concern

In the manufacturing industry, lone workers are any employees who are working unaccompanied. This could include (but is not limited to):

- Employees working after hours in a manufacturing plant, whether operating machinery or cleaning the plant after the day's work is done

- Employees dispatched to a remote location, such as a company depot, without other employees to accompany them

- Employees who are working in the same building as other employees, but out of their sight (for example in a storeroom or basement room, or on the roof of a building whilst other employees are inside)

Lone workers are at particular danger from workplace fatalities because they tend to struggle to get immediate assistance. If a lone worker falls from a height or sustains an electric shock and there is nobody on hand to help or call the emergency services, puts them at significant risk. One example of this sadly occurred in Hemel Hempstead in 2015, when a lone worker was crushed to death by a milling machine. The company he worked for was fine £1 million as it was deemed that this work had not been planned adequately, resulting in the worker in question operating an unsafe machine without proper support from other personnel (more specifically, it was found that other staff members had failed to assess the safety of the milling and angle grinding machines he was using before he began work).

How technology can overcome these risks and reduce injury and fatality figures in the manufacturing industry

Remote monitoring and alert systems can help to ensure lone worker safety in the manufacturing industry. When lone workers are equipped with two way communication devices, they can let their managers know immediately of any difficulties, and if they fail to check in at certain stipulated intervals (say, every half an hour), their manager can instantly raise the alarm. These systems, which ought to be integrated with existing health and safety practices such as regular HSE assessments, can also be designed to automatically alert colleagues to an incident the moment it occurs, even if the user is rendered unconscious. When first aid is provided in a timely fashion, the incident will less likely become something more serious.

Find out more about our lone worker alarm systems

All too often in the manufacturing industry, an injury becomes a fatality because a lone worker is not discovered and aided on time. With our lone worker alarm systems, managers can ensure that every adverse incident involving a lone worker is attended to immediately. Find out more about how our systems work by visiting the following link: http://resources.anttele.com/lone-worker-alarm-systems